此设备为专利,能卸粉状物料,如水泥、矿渣微粉、粉煤灰等。能卸颗粒状,如煤炭、粮食、散装化肥、木薯片等。尤其能卸磨琢性颗粒状物料,如当前无法解决连续封闭无尘卸船的水泥熟料、煤炭等其他物料。

前言:

水泥粉磨站一般都是沿江河湖海而建,它的最大粉尘污染就是港口卸船抓斗卸水泥熟料生产方式,这种落后的卸载操作已有几十年的历史。粉磨站为了解决抓斗卸水泥熟料粉尘污染也采用了以下措施

1、卸料斗加装围板方式(一般4~6米高);

2、卸料斗加装大功率除尘器(装机功率22KWⅹ2,处理风量18000ⅹ2);

3、严控操作规程采用“轻抓慢放”(一个操作过程约需4~6分钟)。

沿江河湖海而建的粉磨站由于自然环境一年四季尤其冬季现场风力较大,虽然采用以上防尘措施操作现场还是粉尘飞扬,粉尘测试远超国家粉尘标准,”轻抓慢放”大大降低了生产效率。并且抓斗卸船清仓时容易造成抓斗砸船砸人的重大人身伤亡事故。 我司经多年的调研和摸索研发了一种集螺旋,提升机,皮带机于一体的新结构水泥熟料连续式卸船机,该卸船机最大特点:全封闭船仓内取料,提升输送,集中多点除尘(除尘最大装机功率15KW 处理风量8000~12000)完全有效控制落料点粉尘问题,实现了无尘卸船。该卸船机将最大磨损点设计在取料头部位,采用高强度耐磨材料制作,并易损部件更换方便(卸熟料5~10万吨更换)更换费用4000元左右,各落料点基本釆用料磨料工艺延长了各落料点溜槽的使用寿命。该卸船机的运行彻底解决了水泥粉磨站卸载水泥熟料的扬尘问题,符合国家蓝天白云的环保政策,利国利民。同时,该卸船机也可以卸煤,木薯片,氧化铝,粮食等颗粒状,粉状物料,卸载船型1千吨~10万吨,卸载量200~1500吨/小时。

【产品介绍 Product Presentation】

专利号: ZL 2013 2 0660073.4、 ZL 2012 1 0140579.2、ZL 2013 1 0507364.4、ZL 2012 2 0200788.7

我司研发生产的水泥熟料卸船机是一种应用特别广泛的港口码头连续卸货装备。此款卸船机能卸粉状物料,如水泥、矿渣微粉、粉煤灰等。并能卸颗粒状,如煤炭、粮食、散装化肥、木薯片等。尤其能卸磨琢性物料,如当前无法解决连续封闭无尘卸船的水泥熟料。

该卸船机通用性强、运行成本低、高效、节能环保、维护保养简单(易损件更换方便)。是一台综合传统物流运输设备(螺旋取料机、斗式提升机、水平皮带输送机)集一身的创新型港口码头卸船装备。

目前散装水泥熟料船卸载方式是传统的抓斗卸船机,配除尘式装料斗,整个卸载过程中粉尘飞扬,场面如同爆破现场一般,对周围环境造成严重污染。本款创新型水泥熟料卸船机可以完全解决当前建材行业共同面临的重大环保难题:如何连续封闭无尘的卸载水泥熟料。

Our cement clinker unloading machine is a port unloading equipment without special request to the ship bulk material.

This unloading machine can unload the powdery materials, such as cement, slag powder, fly ash etc. and remove particulate, such as coal, grain, bulk fertilizer, cassava piece etc. In particular it can discharge wear resistance materials,such as clinker for which continuous closed dust-free unloading could not be down before .

This ship unloader is in strong generality, highly active, energy-saving and environmental protection and simple maintenance. It is an innovative port unloading equipment integrating traditional logistics transportation equipment.(Screw reclaimer, bucket elevator, belt conveyor)

The continuous ship unloader is widely used now all over the world portbecause of the characteristics of high efficiency, energy saving and environmental protection. Continuous type ship unloader is divided into vertical screw shipunloader, belt ship unloader ( skirt edge type, entrainment type) and chain bucket ship unloader according to the different material unloading.

The vertical screw shipunloader and belt type ship unloader have special request to unloading materials. Their unloading material is quite single .And they can not uninstall the mainly raw materials “Cement clinker” from current world cement grinding station. Chain bucket ship unloader is only suitable for discharging large bulk cargo ship above fifty thousand tons because of huge volume of equipment, chain bucket matched with ship tonnage reclaimer.

At present, the ship unloading bulk cement clinker is the traditional grab ship unloader equipped with dust hopper. The whole process of unloading dust. Scenes looks like blasting site causing serious pollution to the surrounding environment.

This innovative cement clinker unloading machine can completely solve the major environmental problem which the current building materials industries are all facing now: How to continuously unload cement clinker Closed dust-freely?

The characteristics of this new cement clinker unloading machine:

It can complete unloading work of cement clinker bulk ship dust-freely.

一:螺旋取料器(The screw dispenser)

① 利用关节式耐磨型大口径变速垂直螺旋。取料器可以纵向180°转动取料,取料灵活,适合大小船型(小1000吨,大10万吨)。取料剩料厚度一般为20公分~40公分左右,大大减轻了清仓机工作量。

② 取料器螺旋叶片采用高耐磨浇铸叶片,有效解决了水泥熟料对螺旋叶片的磨损,提高叶片使用寿命,前端超耐磨螺旋叶片拆卸方便,更换简单。

③ 取料器螺旋叶片取料速度可调,可根据船舱内的物料多少调节,螺旋叶片转速在满仓时保证取料效率,更重要的是在清仓时调低转速,减少叶片的磨损,延长螺旋叶片的使用寿命。

① Using the joint wear large diameter vertical spiral gear. The dispenser can reclaim materials with longitudinal 180 ° rotation, reclaim flexibly, suitable for the size of the ship (1000 tons, 100000 tons). Reclaiming leftover material thickness is abour 20 cm ~40 cm, greatly reduce the workload of cleaning machine.

② The reclaimer’s helical blade is high wear-resistant casting blade whichis effective solution to the cement on the wear of the screw vane and improve the service life of blade. The front super abrasion proof helical blade is convenient to disassemble, replacing simply.

③ Feeding speed of the reclaimer’s helical blade can be adjusted according to the amount of material in the cabin. Helical blade’s speed ensures reclaiming efficiency at full positions.More importantly, it can be adjusted to lower speed at clearance in order to reduce the abrasion of the blade and extend the service life of the spiral blade.

二、斗式提升机(分摆动式倾斜斗式提升机,小车移动式垂直斗式提升机)(Bucket elevator(Swing type inclined bucket type lifting machine, Cart moving vertical bucket type lifting machine))

① 斗式提升机是当前世界上提升各种物料的可靠实用装备。本卸船机通过螺旋取料器取料,再送入斗式卸船机的进料口,之后斗式提升机把物料提升出船舱。这一方式高效、可靠、维护简单。

② 本卸船机配备的斗式提升机分摆动式倾斜斗式提升机,小车移动式垂直斗式提升机。其目的是根据不同船型,在船舱中最大范围的取料卸船。

① Bucket elevator is currently the reliable and practicable equipment over the world for lifting various materials . This ship unloading machine reclaim through the screw dispenser ,then feed into the bucket ship unloader port, then bucket type lifting machine ascends out the cabin material. This approach efficient, reliable, simple maintenance.

② The bucket type lifting machine this ship unloading machine equipped with is divided to swing type inclined bucket elevator and car mobile vertical bucket type lifting machine . Its purpose is according to the different type, taking the maximum range in the cabin of the ship unloader.

三、封闭式水平皮带机(分U型皮带和裙边挡边皮带)(Closed horizontal belt conveyor(devided to U type belt and skirt edge guard belt))

① 皮带输送机,是物流行业最普遍使用的输送装备。本卸船机采用螺旋取料器,在船舱内取料,送入斗式提升机进料口,提升到设定高度后再送入封闭式皮带机进料口,通过封闭式水平皮带输送物料到码头上的指定位置。

② 本创新型水泥熟料卸船机最大特点在于:利用螺旋取料器、斗式提升机和封闭式皮带机各自的特点,经过巧妙的设计结合,形成一个综合性、实用型的物流卸船输送系统。

① Belt conveyor is a conveying equipment most commonly used in the logistics industry. The ship unloading machine adopts the screw dispenser to reclaim in the cabin, then feed the materials into the bucket type lifting machine feeding mouth,, lift them to the setted height and into closed belt machine feeding mouth. It delivers the materials to the specified location on the dock by the enclosed horizontal belt.

② The biggest characteristic of this new cement clinker unloading machine:Ingenious designs and combines the characteristics of the screw dispenser, bucket elevator and closed belt machine ,then formats a comprehensive, practical logistics ship unloading conveying system.

本创新型水泥熟料卸船机的研发成功,将为您的港口提供全面、高效、环保的散料卸载方案。

The successful developing of this new cement clinker unloading machine will provide the bulk load shedding scheme for comprehensive, efficient, environmental protection for your port.

【技术说明 Technical description】

一 概述(Summary)

该卸船机为斗提式连续卸船机,输送物料系统由四部分组成: ①采用螺旋取料机在船舱掘取物料并喂入链斗式提升机;②用链斗式提升机将物料从船舱垂直(或小角度偏斜)提升到所需要的高度并卸到水平输送系统;③通过螺旋给料机将物料从斗提机出料口送到带式输送机;④采用带式输送系统将物料水平或倾斜输送到设置在岸上的皮带输送系统。

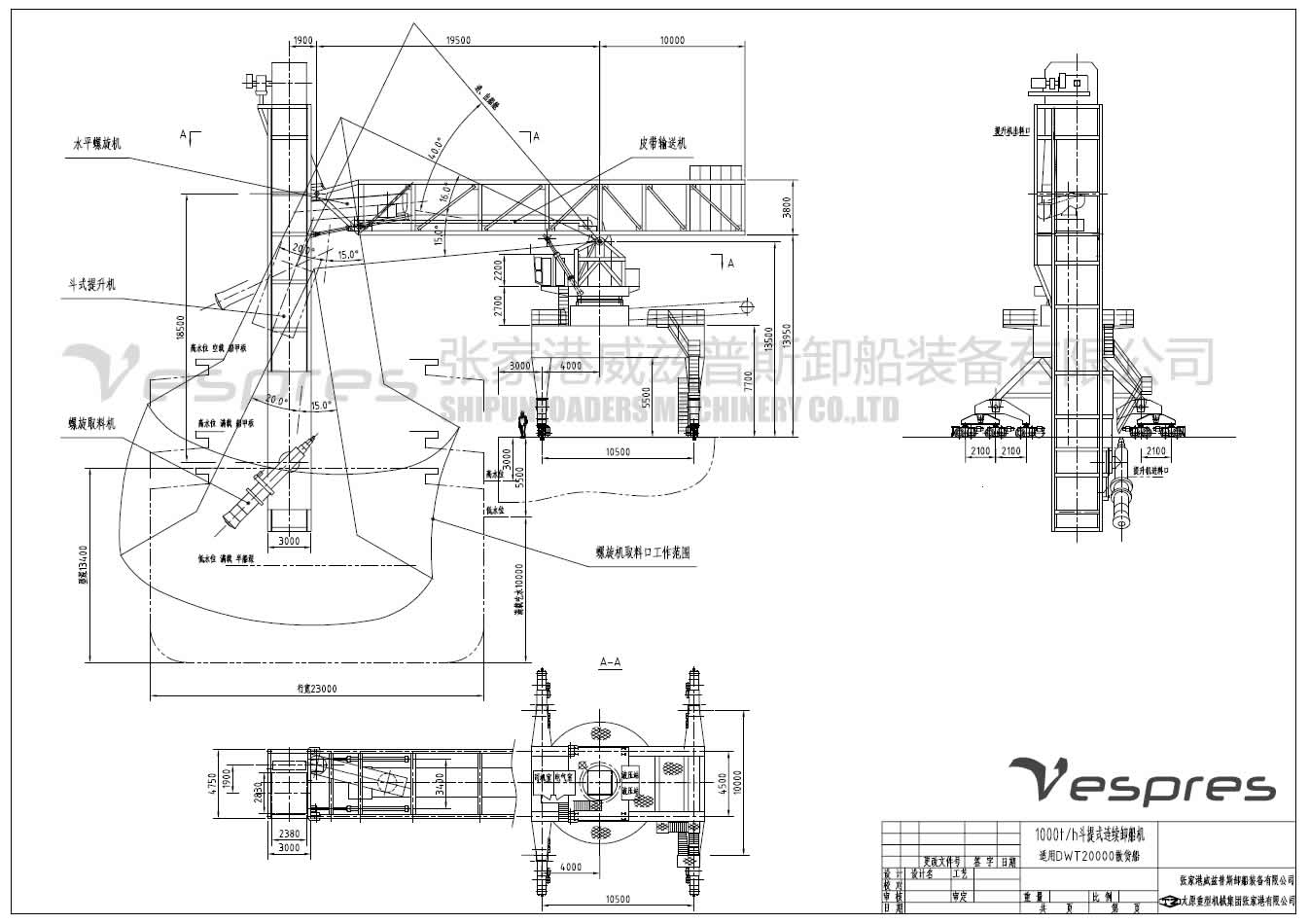

为使该系统能从船舱的任何部分取料并输送到岸上设定的皮带输送系统,卸船机除物料输送系统外,还设有:提升机吊架、吊架摆动油缸装置、臂架、臂架摆动油缸装置、回转台、回转机构、门座结构和运行机构。

提升机吊架下端连接螺旋取料机,可在船舱内前后摆动取料;吊架上端铰接吊挂在臂架的前端,吊架通过摆动油缸可前后摆动,满足取料的变幅要求;臂架通过油缸可作仰俯摆动,同时带动提升机吊架升降,从而满足取料时的升降要求;臂架铰接在回转台上,可通过回转机构左右回转,满足在扇形平面范围取料的要求;门座和卸船机通过大车运行机构沿轨道平行海岸移动,可在更大范围取料。螺旋取料机将所取的物料在提升机吊架下端喂入链斗式提升机进料口,链斗式提升机将物料提升到吊架的顶部提升机出料口,再通过螺旋给料机将物料卸到设置在臂架上的带式输送机上料端,带式输送机沿臂架将物料送到回转中心卸入落料筒,再从设在门座上的带式输送机转送到岸上固定的输送系统。

这种复合式连续卸船机特别适用于颗粒及带小块物料的连续输送,避免了单一采用螺旋输送机卸船易堵塞和易磨损的缺点,适合水泥熟料、散煤等物料的卸船作业。

The ship unloader is bucket type continuous ship unloader. Material conveying system consists of four parts:1, Adopt the screw dispenser to reclaim in the cabin then feed the materials into the chain bucket elevator.2, Lift the materials vertically (Or small angle deflectly) to the requested highth by the chain bucket elevator and unload them to the horizontal conveying system; 3,Send the material from the bucket machine to the belt conveyor by worm feeder;4,Convey the materials horizontally or inclinly to the belt conveyor system setted on the shore by belt conveyor system.

In order to make the system be capable of reclaiming from any part of the cabin, we also equipped this ship unloading machine with : hoist hanger, hanger swing cylinder device, cantilever crane, arm swing cylinder device, truntalbe, slewing gear, valve seat structure and running gear.

Hoist hanger is connected with screw Reclaimer, so it can reclaim in the cabin to and fro. The hanger is hinged with the upper end of hanging in the front arm,so it can swing back and forth through the swinging cylinder meeting amplitude request for reclaiming. The arm can swing upwards and downwards through the oil cylinder and hoist the hanger to lift at the same time meeting lifting request for reclaiming. The arm is hinged on the rotary table。It can circumgyrate leftwards and rightwards through the rotary mechanism meeting reclaiming request in the range of sector plane. Portal and ship unloader move parallel to the coast along the track by the crane traveling mechanism, so it can reclaim on a larger scale. Screw reclaimer will feed the materials into the chain bucket type lifting machine’s feeding mouth in the lower hoist hanger. Chain bucket elevator lift the material to hanger’s top hoist discharging port and then unload them to the belt conveyor ‘s feed end located in the boom through the spiral feeder. Belt conveyors unload the materials to the rotary center and drop them into cylinder along the arm, then transfer them to fixed delivery system on the shore from the door seat belt conveyor.

This composite type continuous ship unloader is suitable especially for continuous conveying in particles and with small pieces of material, avoiding blockage and abrasion defects by using single screw conveyor unloading, suitable for cement clinker, coal and other materials of unloading operation.

二 技术参数(Technical parameter)

1 基本参数(essential parameter)

输送物料 (Delivery of materials) 散煤(Loose coal)

容重(volume-weight ) 0.77 t/m3

额定生产能力(capacity rating) 1400 m3/h

1000 t/h

2设计船型尺寸(Design ship size)

船型(ship type) 散货船20000 DWT

行宽 (line width) 23 m

型深(moulded depth) 13.4 m

空载吃水(light draught) 5 m

满载吃水(load draught) 10 m

设计最高水位(距码头平面)(The highest water level (from the pier plane)) 3 m

设计最低水位(The lowest water level) 5 m

3卸船机大车运行轨道(Ship unloader trolley track)

轨道型号( Track type) P50

轨距 ( track gauge) 10500 mm

最大轮压(Maximum wheel pressure) ≤250 kN

4 输送设备规格(Conveying equipment specifications)

螺旋取料机(Screw Reclaimer) LQ 800

斗式提升机(bucket elevator ) NBH1400E-1300 m3/h

螺旋给料机(worm feeder) LS 1500

带式输送机(belt conveyer) 带宽(tape width)2200 mm

5 卸船机各臂杆摆动角度(The ship unloader arm swing angle)

5.1 斗式提升机吊架(Bucket type lifting machine hanger)

前摆(front swing) 20°

后摆(back swing) 15°

5.2 臂架(cantilever crane)

下俯(nutation) 15°

上仰(卸料时)(Upward (discharge)) 16°

(进出船舱)((in and out of the cabin)) 40°

5.3 螺旋取料机(Screw Reclaimer)

前后摆 (Back and forth) ±90°

5.4 转台(臂架)(Turntable (ARM) )

水平回转 左右±100° (horizontally revolving around left and right )

注(Remark):

设备结构形式、主要尺寸及取料范围参见附图

以上参数及图形均为初步设计数据,仅供用户参考,正式设计会有变动。

实际参数和尺寸可按用户具体要求设计。

Equipment structure, size and material scope see Figure.

The above parameters and graphs for the preliminary design data, for reference of the user, the formal design maybe changed a little.

The actual parameters and size can be designed according to customer’s specific requirements.

顾客订购卸船机需提供以下资料,请认真阅读后,在下方留言或者电话联系:

- 您可以通过下方在线提交表单的方式联系我们,我司将在24小时内给予您电话或邮件回复。

- 您也可以通过下方的电话更快捷的与我们的技术服务工程师直接咨询交流。

Phone: 0086-13336039143

Email: service@vespres.com

[contact-form-7 id=”701″ title=”联系表单 1″]

1、 卸货标的物料名称(如粉煤灰)

2、 码头水文资料

a) 最高潮位水面距码头平面的距离(m)?

b) 最低潮位水面距码头平面的距离(m)?

3、 码头的位置(具体地址)

a) 海港口

b) 内河港口

4、 散装运输船船型

a) 最大载重量多少吨

5、 卸船机的型式要求

a) 固定式?

b) 行走式(需提供码头轮压、轨距)?

c) 卸船机在港口的布置要求,运行距离?

6、 基础资料

a) 电源电压、频率?

b) 工作环境温度?

c) 卸料上岸后续输送型式要求?

d) 卸船的效率要求(T/h)?

7、 当地的环保要求

a) 对粉尘的具体要求等(尽量减少污染)

b) 对噪音的具体要求?

Clients need to submit below information when ordering the ship unloader.Please fill in below column and send them to us service@vespres.com.We will reply to you as soon as possible.You could also contact our engineer by phone.

1、Name of unloading subject matter?

2、Hydrologic data of the wharf:

a) The distance between the surface of the water and the pier plane at highest tide level?

b) The distance between the surface of the water and the pier plane at lowest tide level?

3、Detail address of the wharf:

a) sea port:

b) inland port:

4、Ship form of bulk cargo ship:

a) Maximum load?

5、The type of ship unloader:

a) stationary type?

b) walking type(need information of Terminal wheel pressure and track gauge)?

c) Layout request and range ability?

6、Basic information

a) Supply voltage, frequency?

b) Temperature of working environment

c) Subsequent delivery form request after unloading?

d) Efficiency request(T/h) ?

7、The local environmental protection request:

a) Specific request to dust?

b) Specific request to noise?